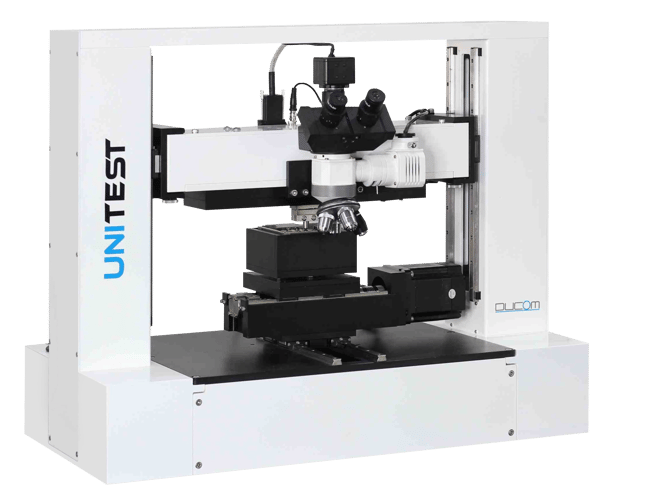

The modular UNITEST platform can be configured to a powerful scratch testing device for precise evaluation of surfaces for damage, delamination and traction force.

Measure traction force, acoustic emission, control temperature, humidity and take high resolution 2D or 3D images of scratches.

Fully compliant with ASTM and ISO test standards.

Tribological characterization of coatings with automated inline microscope.

Damage and failure mechanisms of thin films and coatings under high contact stress can be unambiguously identified using the UNITEST - Scratch Configuration.

Its programmable, closed loop loading system can apply fixed, ramped, stepped or custom loading profiles. Interchangeable load heads give you the flexibility to start with one range, but to evolve as your needs grow. A variety of sensors like acoustic emission, humidity and temperatures are also available to add further insight to your evaluation.

Surface observation add-ons for 2D and 3D surface maps are also available. The data acquisition system can display the image and the test data in a single view for easy evaluation.

Tips

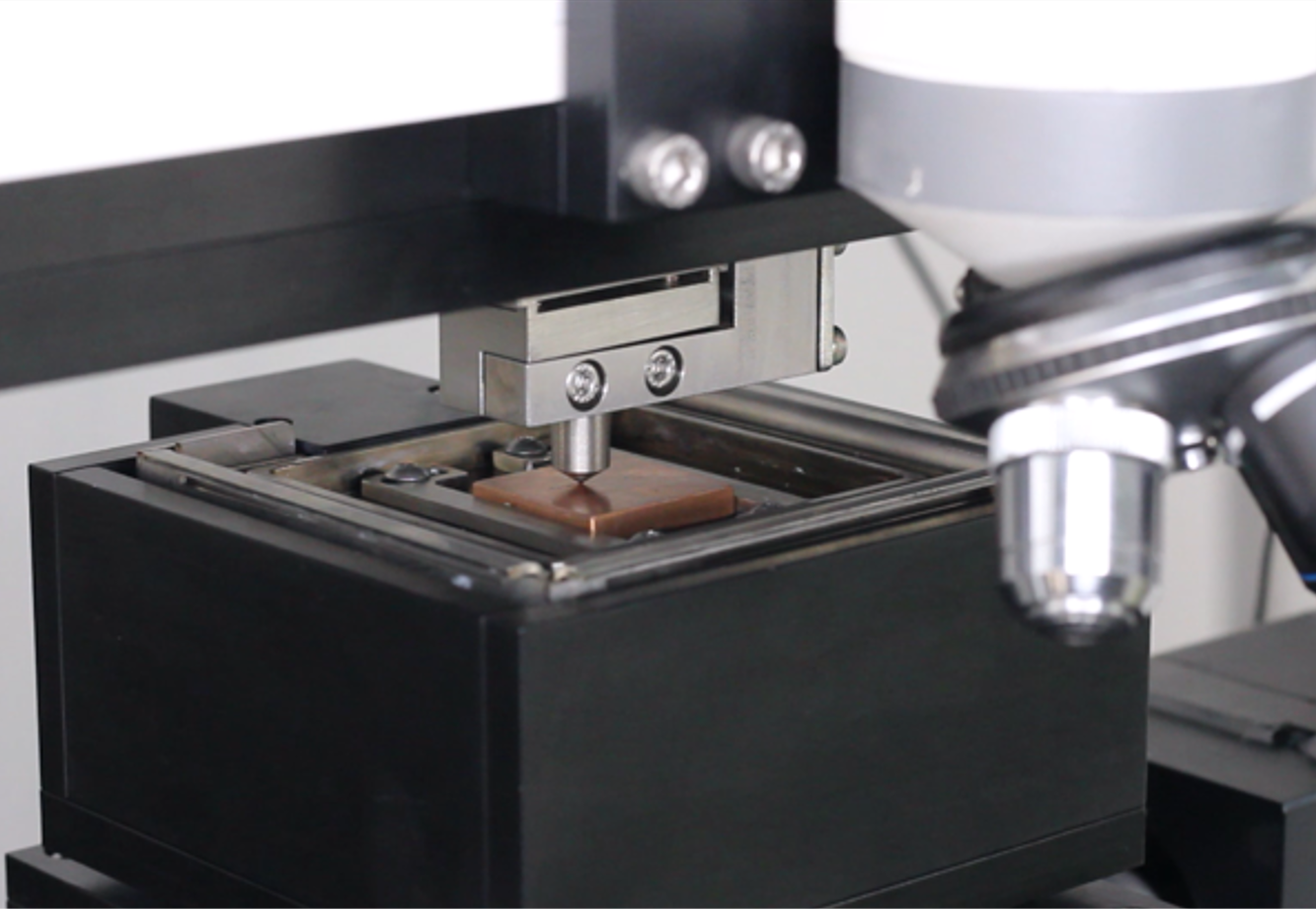

Servo-controlled loading using tandem drive and embedded encoders ensures high level of precision despite the surface waviness. Different tips (Rockwell C, Vickers) can be easily mounted on the movable cross head. Programmable scratch profiles (progressive, constant and step) as well as single point indentation offer flexibility in experimental design.

Interchangeable force sensors mounted on the moving cross head measure the normal and traction force simultaneously. A change in friction force may represent delamination in the coating. The wideband acoustic emission sensor with high sensitivity mounted on the stylus assembly picks up early damage events such as initiation of subsurface cracks. An inline depth sensor measures the penetration depth of the stylus into the material. Automation enables both pre and post test scan and software algorithms report the final true residual depth.

A motorized platform with a bidirectional X-Y stage with long travel offers capability to control the length of scratch as well conduct multiple scratches with offsets. Precise step servo motors with embedded encoders allow for accurate repositioning of the sample between the mechanical head and optical head without backlash. This offers users the advantage to locate specific regions on their sample for conducting tests and imaging the same region post scratch/indentation.

An optical microscope with multi-objective turret and high definition camera captures images of the scratch/scar on the sample. Automated stitching at different magnifications with overlap corrections ensures a high resolution image of the entire scratch without loss of features. The auto-stitched images are conveniently superimposed and mapped to the traction force and acoustic emission data for establishing accurate damage correlations from multiple sensors.

"Ducom UniTest with Inline Imaging is a sophisticated instrument capable of characterization of surface response and damage of materials. In-situ imaging with scratch and indentation modes offers flexibility to probe specific regions of our material in a repeatable manner. Moreover the high resolution stitched images superimposed on the data from other sensors such as traction and acoustic emission provide insights into understanding of damage mechanisms. Such a facility will help us develop better coatings for a variety of applications."

Dr .Udaya Bhat

Professor in Metallurgical and Materials Engineering and Chairman, Central Research Facility, NITK Surathkal, India

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10

Email: info@ducom.com