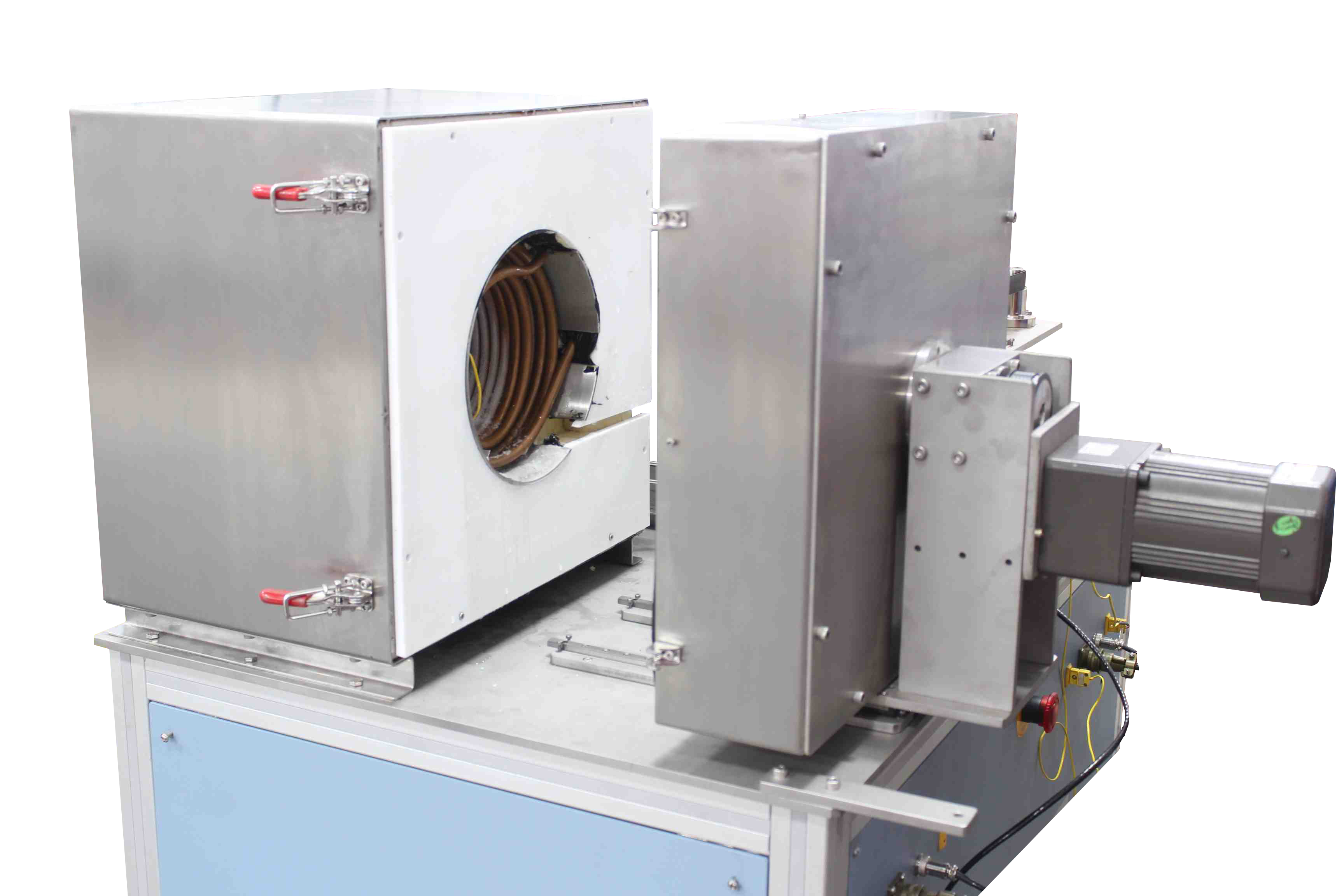

The Ducom Low Temperature Torque Tester (LTT) consists of two separate chambers controlled by an electronic chiller and complies with ASTM D1478, ASTM D4693 and IP 186.

The LTT is used to determine the resistance of a grease to retard the rotation of a slow speed ball or spring bearing at sub-zero temperatures (below -20 °C) by measuring the starting and running torque.

Break-away torque and running torque evaluation of greases at low temperatures

Greases for bearings used in components working at sub-zero temperatures, like in aviation, automotive, defense, agriculture equipment and food storage.

This test module consists of a motor with a drive shaft assembly, a test cage with load disc and bearing housing, a low temperature box and a frictional force sensor. An open ball bearing (No. 6204 size) is packed with grease and it is fixed on the bearing housing of the test cage. The test cage is directly mounted on the shaft driven by the motor (horizontally mounted). The load is applied radially by a 454±3 grams load disc. As the test bearing inner race rotates at 1 rpm, the bearing friction torque (starting and running) is recorded by the load cell, which is connected to the outer race of the bearing through a chord (as per ASTM 1478).

An angular contact bearing (No 7204) is packed with grease and it is directly mounted on the bearing-spindle assembly. The bearing-spindle assembly is then vertically immersed into the low temperature box. The spindle is connected to the motor by a pulley arrangement. The normal load is applied axially using a dead weight of 4.5 kg. The motor starts the rotation of the driver pulley and the same is transmitted to the bearing inner race via the seamless belt. As the test bearing inner race rotates at 1 rpm, the bearing friction torque (starting and running) is recorded by a load cell connected to friction pulley.

The subzero temperature in the test units are maintained by a closed loop temperature control system using the electronic chiller. The chilling system is equipped with a dual stage cascade refrigeration system for precise and stable ultra-low test temperatures. The refrigerant is pumped and circulated at low temperature via copper tubing coils to provide convective cooling to the test bearing. The temperature can be controlled and maintained within + 0.5 °C.

An innovative design and a test area that is easily viewed and accessed make the LTT simple to use. This design has the capability of being upgraded to the ASTM D4693.

USA: +1 (847) 737-1590

India: +91 (80) 4080-5555

Netherlands: +31 (85) 065 74 10

Email: info@ducom.com